If I were you, I would talk to your local GE Fanuc distributor.

Robotc net upgrade#

In fact, if you can get your local GE Fanuc people interested in helping you upgrade to the RX3i platform, your I/O modules will still work with an RX3i CPU and any "standard" programs you may have produced for the 90-30 can be imported into a new application folder for the RX3i. Even though the 90-30 is getting a bit long in the tooth, it is still a viable platform.

Robotc net series#

The Series One Junior has been obsolete for more than 15 years, so that should be the first platform to retire. In addition, we've been hearing blather about the imminent demise of ladder logic as a programming language for a couple of decades now but it's still in widespread use. There are far more PLCs than robots in use in the manufacturing world, so your students are much more likely to be working with PLCs. Thank you in advance for sharing you expertise.

Robotc net update#

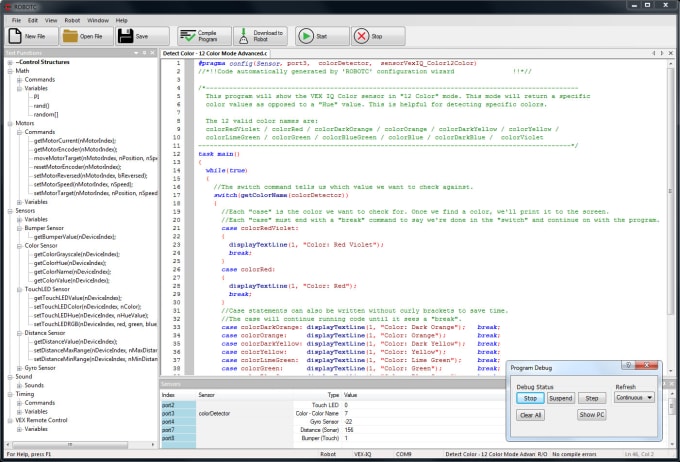

Remove the PLCs? Remove the ladder logic? Update PLCs? If we should update the PLCs can you recommend a replacement PLC? If we should update the PLCs can you recommend inexpensive but intuitive software that utilizes ladder logic? Please remember that we are not a trade school and our courses are designed to fulfill the needs of students who will pursue a wide variety of higher education and career options. My fear is that we should not remove the PLCs and ladder logic components because of what a fundamental niche of automation they fill. We currently have a number of the VEX kits used in other parts of the curriculum. VEX was developed by CMU and is a highly configurable erector set type kit with a programmable “brain” and numerous input/output options. The PLCs used are GE Fanuc series one juniors and a GE Fanuc 90-30.Īn “expert” in the field of robotics education has recommended we drop the PLCs and ladder logic in lieu of an assembly type project using the VEX robotics system and roboC programming. The PLCs control sensors and pneumatic cylinders to perform functions in a simulated assembly scenario. We are currently involved in a curriculum rewrite and are in need of some advice.Ī few weeks of the course has the students programming PLCs with ladder logic through a teach pendant. We view robotics as an aspect of automation. These classes have evolved from a “Power Tech” and “Automation” background. We have a two semester course offerings titled “Robotics I & II”. The classes offered in our Technology Education department are electives for the students. I teach in a public high school with grades 9 and 10 students (average age 15/16 years).

0 kommentar(er)

0 kommentar(er)